ORIGAMI with Beppu Bamboo Craft

One of Beppu’s most popular sightseeing spots, Umi Jigoku (Sea Hell), is a thermal spring that was formed by the eruption of Mt. Tsurumi approximately 1,200 years ago.

Because it contains iron sulfate, the surface of the water shines a vivid cobalt blue, and the spring reaches temperatures of around 98°C (208°F).

At Umi Jigoku, eggs are placed in bamboo baskets and heated by the powerful steam at nearly 98°C to make onsen tamago, known for their rich, creamy yolks. These freshly prepared hot spring eggs are a popular local specialty that visitors can enjoy on the spot.

Jigoku-mushi (Hell Steaming) is a traditional cooking method that makes use of Beppu’s geothermal steam and high-temperature hot spring vapors.

Vegetables, seafood, and meat are placed in bamboo baskets and quickly steamed using natural hot spring steam. Because the ingredients are cooked without excess oil or salt, their natural flavors are preserved and enhanced. Jigoku-mushi is another beloved local specialty, allowing visitors to enjoy freshly steamed dishes unique to Beppu’s hot spring culture.

Madake bamboo, the primary material used in bamboo craft, is valued for its flexibility, strength, light weight, and excellent durability. It is also highly breathable and absorbent, making it well suited to steam and moisture.

In addition, bamboo regenerates quickly and places a low burden on the environment, enabling a circular approach to craftsmanship that makes the most of natural materials.

New bamboo craft pieces often have the fresh green hue of young bamboo or a soft beige tone. Over time, as they are exposed to light and air, the surface gradually deepens into warm amber and rich brown shades.

With continued use, the bamboo develops a gentle luster and a deeper character, becoming a tool that feels uniquely personal and naturally fits into everyday life.

Beppu bamboo craft is known for its soft golden luster, the beauty of its aging over time, and its finely detailed weaving combined with long-lasting strength.

Fresh green bamboo harvested from bamboo groves cannot be used for bamboo craft in its raw state. To make it suitable, the bamboo undergoes a process known as yunuki (hot-water treatment), which transforms it into white bamboo that is flexible, easy to work with, and resistant to decay.

However, freshly cut bamboo is large and heavy, and the yunuki process is carried out in harsh conditions—intense heat in summer and bitter cold in winter. As a result, the shortage of successors has become a serious challenge.

At Nagai Seichiku, the only remaining bamboo processing workshop in Beppu, Shigeyuki Cha, the company’s president, continues to carry out the yunuki process entirely on his own.

He previously worked in the financial sector in Tokyo. He later joined Nagai Seichiku after becoming interested in bamboo craft through a class he attended as a hobby.

Today, in addition to producing bamboo materials, he is also engaged in creating unique in-house products such as bamboo tumblers and speakers.

For Beppu bamboo craft, which is distinguished by its precise and delicate weaving, strong and high-quality bamboo materials are essential.

Nagai Seichiku plays a vital role not only in Beppu, but also in supporting bamboo craft across Japan.

The Yunuki Cauldron

After some time, the bamboo is removed from the cauldron, and the white oil that rises to the surface of the bamboo is wiped off by hand while it is still hot.The bamboo is then turned over, and the same process is repeated once more.

The fuel used for the cauldron is made from bamboo offcuts generated at the workshop.

Water and caustic soda are added to the cauldron, and the bamboo is placed inside once the water comes to a boil.

After the hot-water treatment is complete, the bamboo is stood upright and left to dry in the sun.

After the hot-water treatment is complete, the bamboo is stood upright and left to dry in the sun.

When developing the bamboo dripper holder, the process proved challenging, as artisans in Japan capable of expressing the ideal design through bamboo craft have been steadily decreasing in number.

After a long search, we encountered Nanpu Kogei. Through repeated prototyping and close collaboration, we were finally able to bring the envisioned dripper holder to life.

Nanpu Kogei was founded in 1979 in Beppu City, Oita Prefecture—an area known for its thriving bamboo craft industry. Today, the company is based in Hiji Town, Oita Prefecture, where it continues to produce and sell bamboo products.

In the world of bamboo craft, there are broadly two paths: individual artists who create one-of-a-kind works, and industrial producers where multiple artisans work together to manufacture household goods.

Nanpu Kogei belongs to the latter, producing bamboo items for everyday use. In addition to classic products such as baskets and strainers, the company also pursues unique product development, including diffusers made with essential oils extracted from bamboo.

As the number of makers declines and traditional techniques risk being lost, Nanpu Kogei constantly considers what can be done to preserve the craft for the future—and how to encourage more people to use bamboo craft in their daily lives, says Chairman Mr. Ikura.

According to Mr. Ikura, one of the greatest differences between Japanese bamboo and bamboo found overseas lies in the beauty of the material itself.

While bamboo used abroad is often processed after removing the outer skin, Japanese bamboo benefits from the country’s soil and climate, resulting in a naturally beautiful surface. This allows artisans to create bamboo craft that highlights the material’s original texture and appearance.

In recent years, Nanpu Craft has also been developing new forms of bamboo craft by dyeing the outer surface with natural materials such as lacquer, in an effort to share the appeal of bamboo craft with a wider audience.

How the ORIGAMI Dripper Holder [Rinko Weave] Is Made

How the ORIGAMI Dripper Holder

[Rinko Weave] Is Made

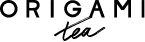

After undergoing hot-water treatment and sun-drying, the bamboo is prepared for bamboo craft by being split into increasingly finer strips, forming thin bamboo splints.

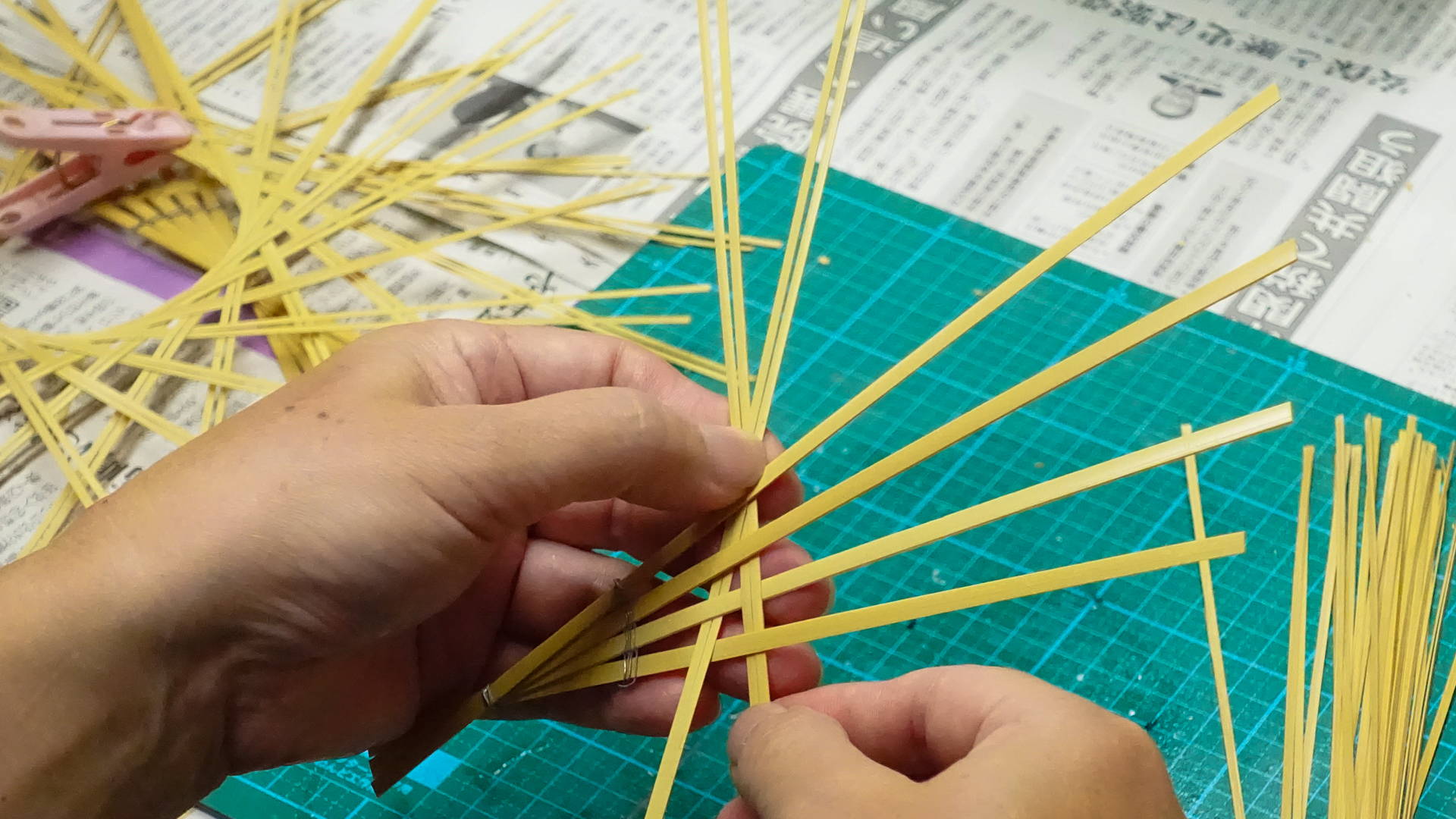

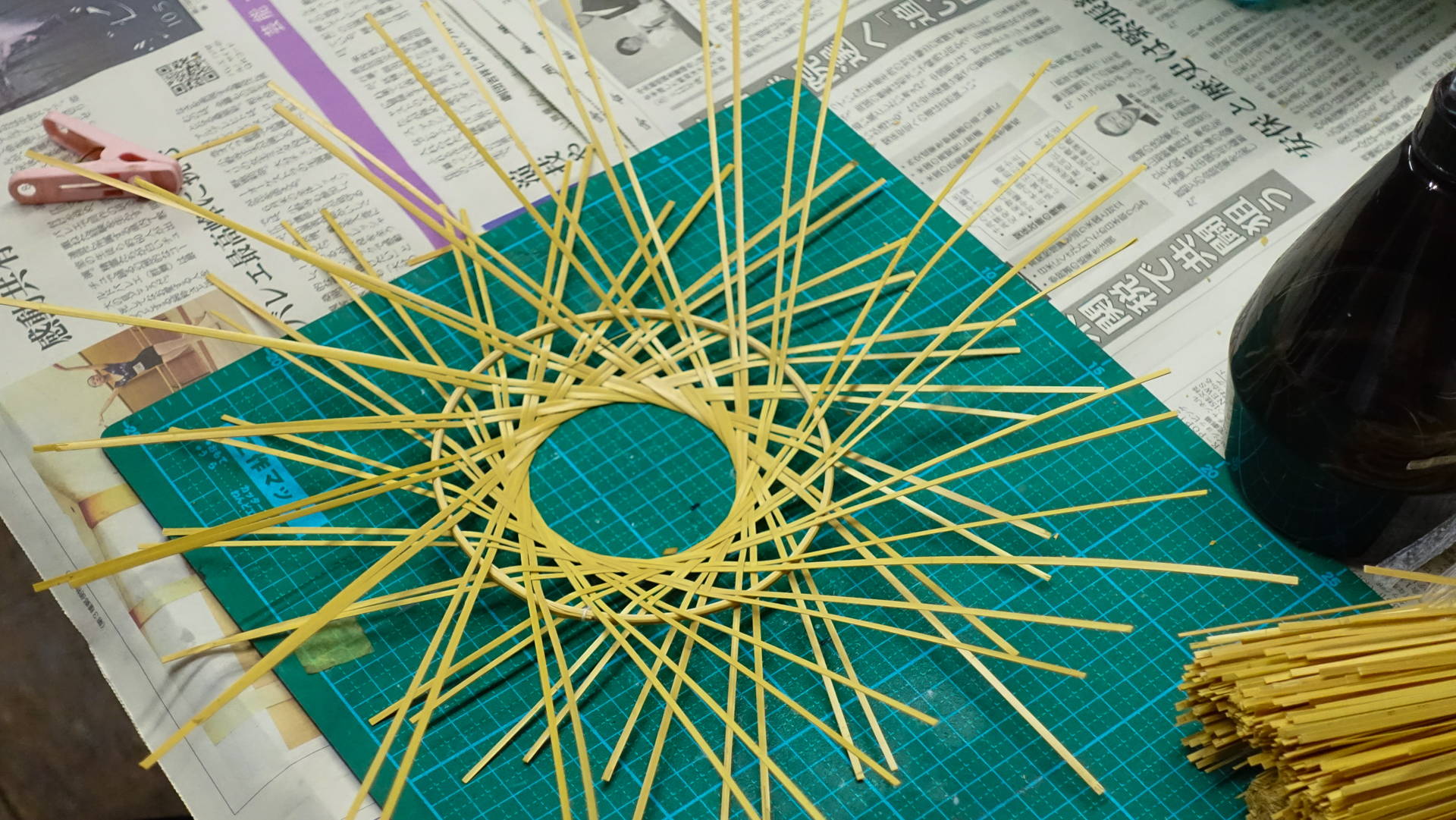

Beppu bamboo craft features a variety of weaving techniques. For this dripper holder, we chose a method known as Rinko weaving, in which bamboo splints are crossed diagonally and woven in overlapping circular motions.

Rinko weaving is valued not only for its strength, but also for its distinctive appearance, combining dimensionality with a sense of lightness.

To ensure a precise fit with the ORIGAMI dripper, the inner diameter of the holder is adjusted using a wooden mold. From there, the shape is refined by hand as the weaving progresses, with each piece carefully formed by the artisan.The finishing process involves trimming the ends of the bamboo splints with scissors. No adhesives are used.

Through the skill and intuition of experienced craftsmen, each dripper holder is shaped into a durable and beautifully crafted tool.

With the cooperation of the following partners in development and research

Manyo Co., Ltd.

2-10-33 Ishigaki-higashi, Beppu-shi, Oita 874-0919, Japan

Nanpu Kogei Co., Ltd.

879-1509, Japan1231-5 Minamihata, Hiji-machi, Hayami-gun, Oita

Nagai Seichiku Co., Ltd.

3-14 Hikari-machi, Beppu-shi, Oita 874-0930, Japan