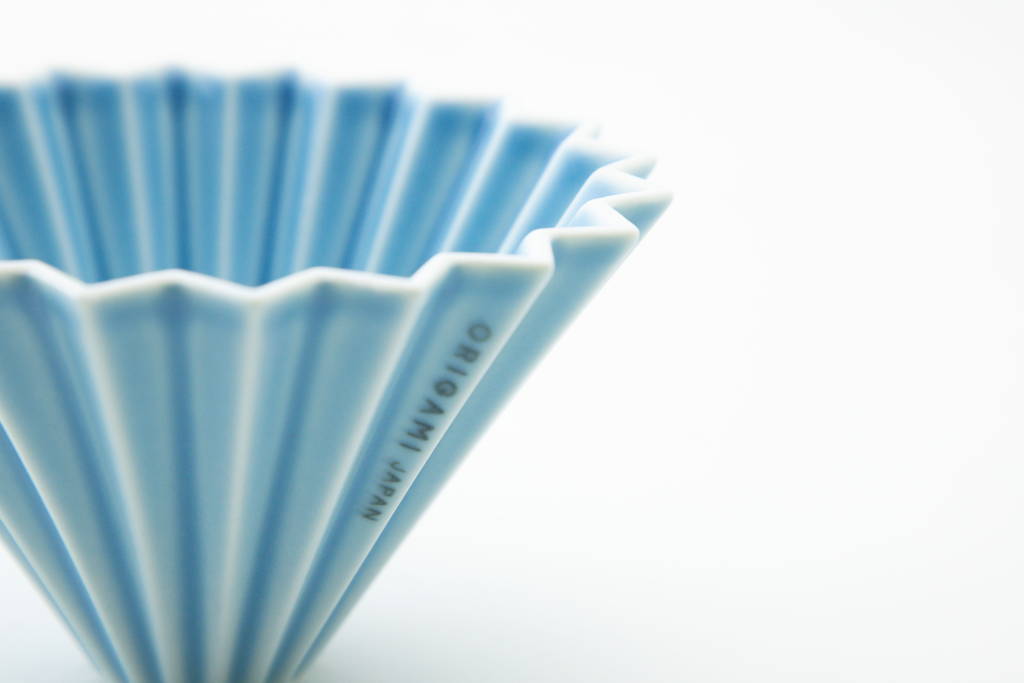

検品後、良品として出荷させていただく商品にも、下記の様な現象が生じる場合がございます。 |

ロゴのにじみ、かすれ ORIGAMI のロゴは下絵付けという技法で描かれており、釉薬の下に印刷しています。 |

鉄粉 白いものであっても、器の原料となる土には鉄分が含まれており、器を焼くと表面に黒い点となって現れます。 |

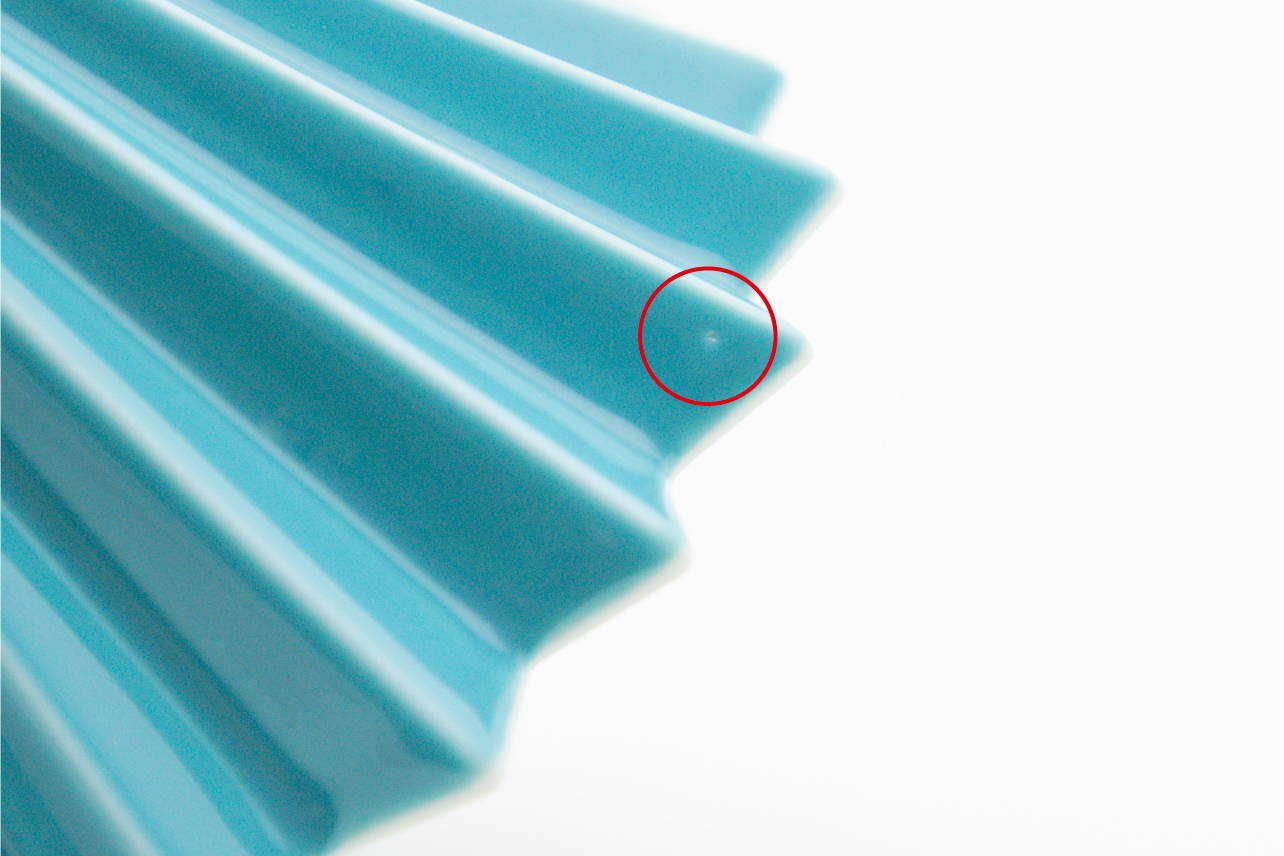

ピンホール 釉薬のかかった器には、ピンでついたような小さな陥没がみられる事があります。 |

釉薬(色、質感)の個体差 季節や気温などの自然条件や、釉薬と焼成する際の火加減の影響によって、磁器は様々な表情を見せます。 |

(左)濃い(右)薄い |

色、質感のむら 器の形状・厚みにより、釉薬のかかる厚みが異なったり、火の当たり具合が異なることによって、1 つの器の中においても、色の表情や質感が均一ではない箇所がある場合があります。 |

色むらの例 |

表面に細かな凹凸が出ている例 |

表面に多数の小さな穴がある例 |

黒のカッピングスプーンの柄の裏の一部分が白くなっている場合がございますが、これは製造時に吊り下げて焼成されるため、その一部分に釉薬がかからないことによるものです。欠けなどの破損ではございません。 |

重量・サイズ 製造のロットや釉薬により、同じ製品でも重さやサイズには個体差があります。 |